about cnc machine wikipedia Within the numerical systems of CNC programming, the code generator can assume that the controlled mechanism is always perfectly . See more Example of a large trendy eat-in kitchen design in Florence with a drop-in sink, flat-panel cabinets, white cabinets, stainless steel countertops, metallic backsplash, stainless steel appliances and an island.

0 · who invented cnc machine

1 · when were cnc machines invented

2 · numerically controlled machines

3 · how does a cnc machine work

4 · history of cnc machine pdf

5 · computer numerically controlled machines

6 · cnc machine history

7 · cnc machine basic knowledge

As Republicans took control of the House on Tuesday, they wasted no time in erasing a symbol of the previous era. They removed the metal detectors that stood outside the House chamber for the.

In machining, numerical control, also called computer numerical control (CNC), is the automated control of tools by means of a computer. It is used to operate tools such as drills, lathes, mills, grinders, routers and 3D printers. CNC transforms a piece of material (metal, plastic, wood, ceramic, stone, or composite) . See moreMotion is controlling multiple axes, normally at least two (X and Y), and a tool spindle that moves in the Z (depth). The position of the tool is driven by direct-drive stepper motors or servo motors to provide highly accurate . See more

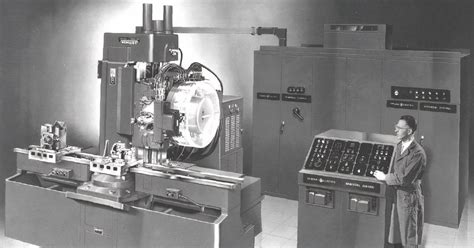

The first CNC machines were built in the 1940s and 1950s, based on existing tools that were modified with motors that moved the tool or part to follow points fed into the system on See moreMany other tools have CNC variants, including:• 3D printing• See moreWithin the numerical systems of CNC programming, the code generator can assume that the controlled mechanism is always perfectly . See moreNow the CNC in the processing manufacturing field has been very extensive, not only the traditional milling and turning, other machines and equipment are also installed with the corresponding CNC, which makes the manufacturing . See more

who invented cnc machine

In CNC, a "crash" occurs when the machine moves in such a way that is harmful to the machine, tools, or parts being machined, . See more

metal fabrication birmingham uk

In numerical control systems, the position of the tool is defined by a set of instructions called the part program. Positioning control is handled using either an open-loop or a closed-loop system. In an open-loop system, communication takes place in one . See moreThe history of numerical control (NC) began when the automation of machine tools first incorporated concepts of abstractly programmable logic, and it continues today with the ongoing evolution of computer numerical control (CNC) technology. The first NC machines were built in the 1940s and 1950s, based on existing tools that were modified with motors that moved the controls to follow points fed into the system on punched tape. .

A computer numerical control (CNC) router is a computer-controlled cutting machine which typically mounts a hand-held router as a spindle which is used for cutting various materials, . computer numerical control (CNC), in manufacturing, the control of a device, particularly machine tools, by direct input of data from a computer program. It is a principal . Have you ever thought about the history of CNC machines? What do you think people would say to machines making products/tools with little guidance some centuries ago? CNC machining of the present features .

What is CNC: CNC stands for computer numerical control, which is a process of using computer software to control the movement and operation of machines that can cut, carve, or engrave materials. Types of CNC machines : . CNC (computer numerical control) machining is a popular manufacturing process that uses computerized controls to automate parts production. Today, we’ll look at what CNC machining is, how it works, and the .A machine tool has three basic elements: A work-holding device for holding the material, or workpiece. A tool-holding device for holding the tool. A method for guiding the movement of .CNC machining is a subtractive manufacturing process that employs computerized controls and machine tools to remove layers of material from a stock piece, known as the blank or workpiece, to produce a custom-designed .

In machining, numerical control, also called computer numerical control (CNC), [1] is the automated control of tools by means of a computer. [2] . It is used to operate tools such as drills, lathes, mills, grinders, routers and 3D printers.The history of numerical control (NC) began when the automation of machine tools first incorporated concepts of abstractly programmable logic, and it continues today with the ongoing evolution of computer numerical control (CNC) technology.A computer numerical control (CNC) router is a computer-controlled cutting machine which typically mounts a hand-held router as a spindle which is used for cutting various materials, such as wood, composites, metals, plastics, glass, and foams.

CNC machining is the process of using a computer-driven machine tool to produce a part out of solid material in a different shape. The CNC depends on digital instructions usually made on Computer Aided Manufacturing (CAM) or Computer Aided Design (CAD) software like .computer numerical control (CNC), in manufacturing, the control of a device, particularly machine tools, by direct input of data from a computer program. It is a principal element of computer-integrated manufacturing. CNC is also essential to the operation of industrial robots.

Have you ever thought about the history of CNC machines? What do you think people would say to machines making products/tools with little guidance some centuries ago? CNC machining of the present features improved computerized features due . What is CNC: CNC stands for computer numerical control, which is a process of using computer software to control the movement and operation of machines that can cut, carve, or engrave materials. Types of CNC machines : There are different types of CNC machines, such as routers, mills, lathes, lasers, and plasma cutters. CNC (computer numerical control) machining is a popular manufacturing process that uses computerized controls to automate parts production. Today, we’ll look at what CNC machining is, how it works, and the advantages and challenges of this process. We’ll also explore the various applications of CNC machining and the future of this field. 1.A machine tool has three basic elements: A work-holding device for holding the material, or workpiece. A tool-holding device for holding the tool. A method for guiding the movement of the tool relevant to the workpiece or material. A CNC lathe designed for cutting wood. A lathe is one of the oldest types of machine tools. It is most commonly .

CNC machining is a subtractive manufacturing process that employs computerized controls and machine tools to remove layers of material from a stock piece, known as the blank or workpiece, to produce a custom-designed part 1. These computerized machines, called CNC machines, are capable of operating with high precision and consistency.In machining, numerical control, also called computer numerical control (CNC), [1] is the automated control of tools by means of a computer. [2] . It is used to operate tools such as drills, lathes, mills, grinders, routers and 3D printers.

The history of numerical control (NC) began when the automation of machine tools first incorporated concepts of abstractly programmable logic, and it continues today with the ongoing evolution of computer numerical control (CNC) technology.A computer numerical control (CNC) router is a computer-controlled cutting machine which typically mounts a hand-held router as a spindle which is used for cutting various materials, such as wood, composites, metals, plastics, glass, and foams.CNC machining is the process of using a computer-driven machine tool to produce a part out of solid material in a different shape. The CNC depends on digital instructions usually made on Computer Aided Manufacturing (CAM) or Computer Aided Design (CAD) software like .computer numerical control (CNC), in manufacturing, the control of a device, particularly machine tools, by direct input of data from a computer program. It is a principal element of computer-integrated manufacturing. CNC is also essential to the operation of industrial robots.

Have you ever thought about the history of CNC machines? What do you think people would say to machines making products/tools with little guidance some centuries ago? CNC machining of the present features improved computerized features due . What is CNC: CNC stands for computer numerical control, which is a process of using computer software to control the movement and operation of machines that can cut, carve, or engrave materials. Types of CNC machines : There are different types of CNC machines, such as routers, mills, lathes, lasers, and plasma cutters.

CNC (computer numerical control) machining is a popular manufacturing process that uses computerized controls to automate parts production. Today, we’ll look at what CNC machining is, how it works, and the advantages and challenges of this process. We’ll also explore the various applications of CNC machining and the future of this field. 1.A machine tool has three basic elements: A work-holding device for holding the material, or workpiece. A tool-holding device for holding the tool. A method for guiding the movement of the tool relevant to the workpiece or material. A CNC lathe designed for cutting wood. A lathe is one of the oldest types of machine tools. It is most commonly .

Yes, you can mix and match white and stainless steel appliances, though it is important to consider the overall design of your kitchen before making a decision. Stainless steel is a .

about cnc machine wikipedia|history of cnc machine pdf